- #Valve stem remover without losing charge driver

- #Valve stem remover without losing charge free

- #Valve stem remover without losing charge crack

For example, many alloy wheels require a clamp-in type valve stem with a threaded metal nut.Īlso, be sure that when you are removing a valve stem you know whether the vehicle is equipped with TPMS. Never assume the old valve stem is the correct one for the application because it may have been previously replaced.Īlways use a replacement valve stem that correctly matches the type of wheel and vehicle application. Keep in mind that a good valve cap costs pennies, but it can save a great deal of trouble. This way, even if the valve core leaks, the air inside the tire will be contained by the cap. Also inspect the valve hole for nicks, burrs or other roughness that could damage a new stem or prevent a leak-free seal.Īnother safety step to improve the odds against air loss involves a self-sealing valve stem cap that has been securely screwed down on the valve stem itself. If you see any white powder around the gasket seal, then remove the stem and replace either the seal or the whole valve stem. This is especially true for alloy wheels with metal valve stems where the wheel is made from one metal and the stem from another. If the owner of a vehicle is a fast driver, centrifugal forces occurring at high speed can cause a longer valve stem to bend and lose air.Īlways check for any signs of corrosion around the wheel’s valve stem hole. A longer stem is easier to get knocked off. The same holds true with rubber valve stems, but they tend to be a bit more forgiving.Īs a general rule of thumb, use the shortest valve stem possible. You want the gasket seal to be tight, but you don’t want to ruin the seal by overtightening it. This is particularly true with metal valve stems. Once you’ve assured yourself that the core is working properly, the only other caution is not to overtighten the valve core when you re-install it.

#Valve stem remover without losing charge free

While looking at the valve stem, make sure the core is free of dirt and debris, which could cause interference with the valve function. The part numbers affected by the recall are TR-413, TR-413CH, TR-414, TR-415, TR-418 and TR-423.Īside from recall issues, valve stems deserve a good look and service every time a customer’s vehicle comes in. So, the only way to know if the valve stems on a vehicle are from these Chinese makers is to dismount the tires so the numbers on the bottom of the valve stem inside the wheel can be read. Unfortunately, there are no external markings on the valve stems to identify their source.

#Valve stem remover without losing charge driver

Sudden loss of air pressure at highway speeds can be very dangerous and may cause the driver to lose control and have an accident or rollover.

#Valve stem remover without losing charge crack

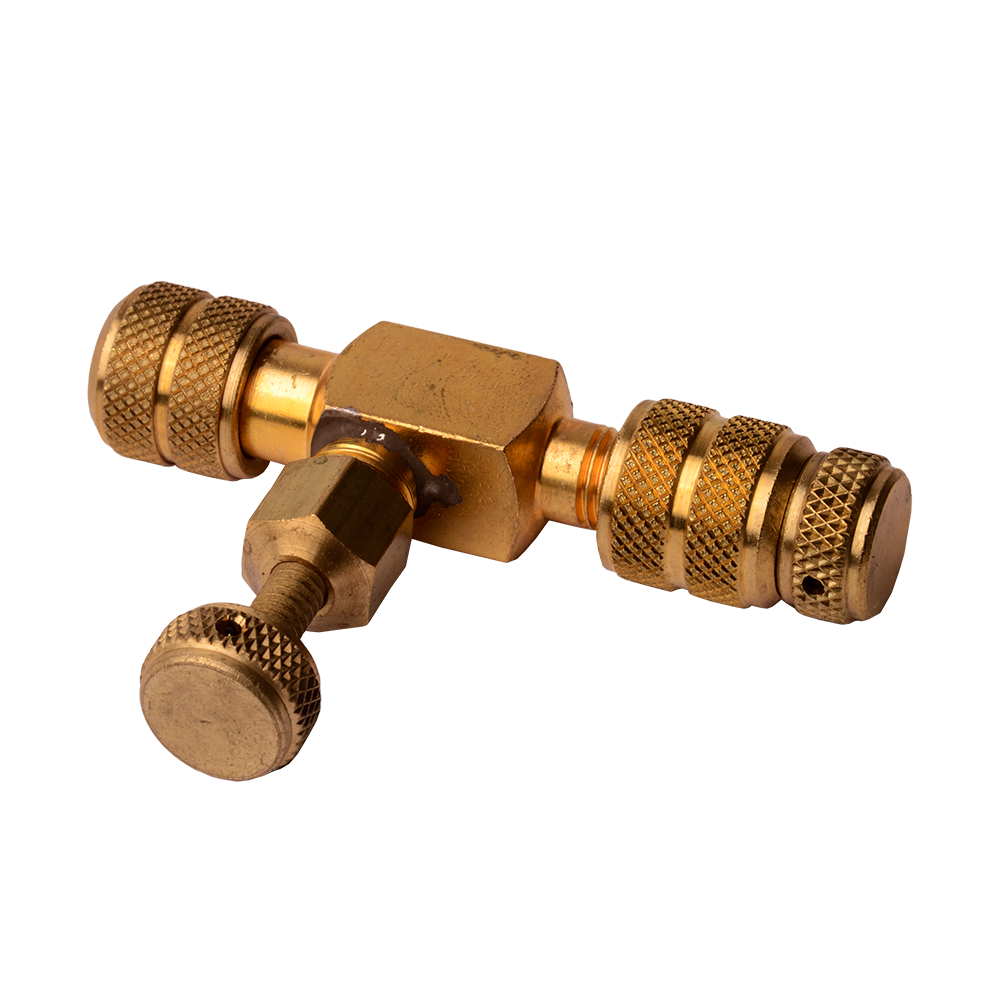

If you see any visible crack or hear air hissing from the base of the valve stem, it is defective and must be replaced.įailure to replace the valve stem may cause the tire to lose air or suddenly go flat. Examine the valve stem and flex it in a circular motion with your finger. If you have installed tires with new rubber valve stems in 2007 and even last year, you should inspect these valve stems for cracks. to many independent tire dealers through a number of vendors. In this case, the stems were distributed in the U.S. Because these pint-sized units perform such a vital task, any news about problems must be taken seriously. The rubber valves have been updated through the years and offer much more flexibility than the 100-year-old original.Īll of us remember the May 8, 2008, recall notice involving as many as 6 million defective Chinese-made automotive tire valve stems. Regarding tire stems themselves, some are made of metal that has been chrome plated, while others are made of rubber. There are at least seven different sizes of valve inserts for today’s tires, and a few dozen different lengths are made.

The majority are machined from brass and then chrome plated. Tire valve cores can be made with several different materials, including brass, ceramic and plastic.

In fact, everyone I’ve ever talked with has recommended that a new tire valve should be included with every new tire installation some dealers even give them away as an added sales perk. My only suggestion is that you cover your labor cost and don’t gouge the customer. When it comes to tire valves, buy high quality units for pennies on the dollar and charge your customers what you will.

While it’s most important to approach this subject from a safety standpoint, it’s also handy to keep in mind the benefit to your bottom line that valve stems offer. It’s not that complicated to understand a standard (non-TPMS) tire valve, but if a mistake occurs in mounting or demounting, or a hard hit on a curb is not inspected closely, you might want to find your lawyer’s card in the Rolodex. The lowly tire valve operates just the way it did when it first found its way onto an automobile tire back in 1898.

0 kommentar(er)

0 kommentar(er)